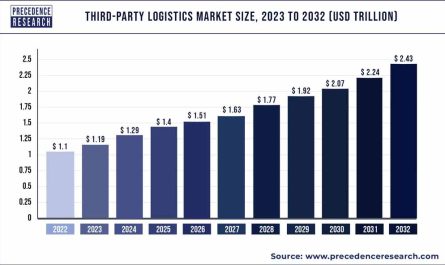

The automotive aluminum extrusion market size is expected to hit over US$ 141.40 billion by 2032 from at US$ 64 billion in 2022, growing at a CAGR of 8.30% from 2023 to 2032.

The automotive aluminum extrusion demand is expected to increase as a result of increasing demand for light weight vehicles and electric vehicles in the market. In order to new alloy processing technologies for lightweight applications, companies in the automotive aluminum extrusion industry need to ramp up their research and development activities.

The companies have started working with research and development teams to manufacture extruded components that meet the automobile manufacturer’s criteria. The vehicle development time can be cut in half by using rapid prototyping. For collision, towing, and assembly operations, research and development centers undertake simulation and accuracy testing.

Get a Sample: https://www.precedenceresearch.com/sample/1446

Scope of the Automotive Aluminum Extrusion Market

| Report Coverage | Details |

| Market Size in 2023 | USD 68.99 Billion |

| Growth Rate From 2023 to 2032 | CAGR of 8.30% |

| Revenue Projection by 2032 | USD 141.40 Billion |

| Largest Market | Asia Pacific |

| Fastest Growing Market | North America |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Segments Covered | Type, Vehicle, Aluminum Grade, Region |

| Companies Mentioned | Hindalco Industries Ltd., QALEX, Arconic Corporation, Constellium N.V., Norsk Hydro ASA, Bonnell Aluminum, China Zhongwang Holdings Ltd., ETEM Group |

Market Dynamics

Drivers

Surge in production of electric vehicles

Due to their numerous advantages over gasoline-powered vehicles, electric vehicle demand and production have increased dramatically in recent years. Since oil and air filters, fan belts, timing belts, head caskets, and spark plugs do not need to be replaced, fuel-powered vehicles are more cost-effective and efficient. As a result, electric vehicles are rapidly replacing gasoline-powered vehicles as the preferred mode of transportation, limiting the growth of the gasoline-powered vehicle industry. Furthermore, because of improved vehicle dynamics and traction control, automakers are concentrating on the development of electric vehicle components using the aluminum extrusion process. As a result, increased production of electric vehicles is expected to propel the automotive aluminum extrusion market forward.

Restraints

High cost of aluminum

The cost of aluminum is high as compared to other types of metals such as steel and copper. Moreover, because aluminum cannot withstand the same amount of pressure as steel, more of it is necessary to assure the structure’s strength, implying that using it in particular designs may cost more in the long run. As a result, the high cost of aluminum is restricting the growth of automotive aluminum extrusion market.

Opportunities

Increase in demand for zero emission or fuel-efficient vehicles

Since gasoline is a fossil fuel, it is not a renewable source of energy and will be depleted in the future. To support sustainable development, alternative fuel sources must be developed and used. This entails the use of zero emission vehicles, which do not require gasoline and are more cost effective than conventional vehicles. Because of the recent increase in the price of gasoline and diesel, there has been an increase in demand for fuel-efficient vehicles. As a result, consumers have begun to prefer zero-emission or fuel-efficient vehicles. Because it is applicable in the automobile industry, this consumer trend is contributing to the growth of the automotive aluminum extrusion market.

Challenges

High maintenance costs

The automotive aluminum extrusion is usually more expensive than normal aluminum extrusion. This is due to the additional components that have been installed in these devices and equipment. Because some parts of these devices wear out faster than traditional ones due to a lack of lubrication in the majority of these extruders, these machines require extensive regular maintenance to increase efficiency. Furthermore, unlike traditional extruders, which typically have a longer life for such parts, the parts must be replaced on a regular basis. As a result, a large amount of capital is required for the operation and maintenance of automotive aluminum extruders. Thus, the high maintenance costs are limiting the global automotive aluminum extrusion market’s growth.

Regional Snapshot

North America region is expected to witness a remarkable CAGR during the forecast period. North America is expected to have the strongest sales growth during the forecast period. Aluminum extrusion is utilized in automobiles, buses, trucks, trailers, and rail, and the market is rising as a result of improved fuel economy and performance.

Asia-Pacific region accounted largest revenue share in 2020. The countries such as China, Japan, India, and South Korea show the highest growth in the region. The governments in numerous countries of the Asia-Pacific region are taking steps to upgrade existing infrastructure and expand the development of green buildings as a result of rapid urbanization and the growing global population. The demand for aluminum extrusion in the Asia-Pacific region is increasing as a result of this factor.

Read Also: Micro-mobility Market Size to Surpass US$ 11.83 Bn by 2032

Report Highlights

- Based on the type, the sub-structures segment dominated the global automotive aluminum extrusion market in 2020 with highest market share. This is attributed to the increased demand for light weight vehicles.

- Based on the vehicles, utility vehicle segment is estimated to be the most opportunistic segment during the forecast period. This is attributed to the increased in demand for MUVs and SUVs.

Some of the prominent players in the global automotive aluminum extrusion market include:

- Hindalco Industries Ltd.

- QALEX

- Arconic Corporation

- Constellium N.V.

- Norsk Hydro ASA

- Bonnell Aluminum

- China Zhongwang Holdings Ltd.

- ETEM Group

- EMERUS

- ST Extruded Products Germany GmbH

Segments Covered in the Report

By Type

- Sub-structures

- Door Beam

- Bumpers

- Pillars

- Sub Frames

- Seat Back Bar

- Front Side Rail

- Space Frames

- Body Panels

- Others

By Vehicle

- Mini-compact

- Supermini

- Compact

- Mid-size

- Executive

- Luxury

- Utility Vehicles

- Light Commercial Vehicles

- Heavy Commercial Vehicles

- Buses & Coaches

By Aluminum Grade

- 5000 Series

- 6000 Series

- 7000 Series

- Others

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Rest of the World

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/